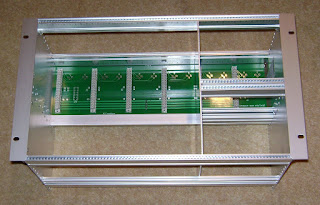

The mix amps are nearing completion. These amps are responsible for raising the mix bus signals back up to line level. The Twin Line Amp (TLA) was designed specifically with this in mind and two such boards are used to provide the four required bus amps - two for the L&R master and two more for the two AUX buses. The PCBs are shown below:

The TLA board is very similar to the mic preamps. The same three tubes are used in the same topology. The main differences are that in the TLA the mic/line/pad/phase/48V switches have been removed and the stepped gain control has been replaced by a trimmer. The space made available by these changes has allowed an extra input transformer to be fitted. The TLA therefore provides two uncommitted line amplifiers with gain variable from 6dB to 40dB and a pair of uncommitted input transformers. The transformer footprint allows 10K:10K bridging or 1:10 mic input transformers by Cinemag, Jensen or Sowter to be fitted.

For operation as a mix amp no transformer is needed. The AUX send mix amp is the PCB at the bottom of the picture. The bus inputs from the edge connector are simply connected direct to the AUX send master pots (each 10K log) and thence to an amplifier which provides the necessary gain make up to compensate for the passive mix bus loss and any gain 'in hand' required for the master fader plus any loss in the output transformer. With four channels feeding the AUX buses via 47K resistors and with a 10K master AUX pot, the total bus loss is close to 19dB. So with 0dB in hand on the AUX send master control, the mix amp gain would need to be set to 19dB. However, since a balanced output is required, a 2K4:600 transformer is fitted externally which drops the level by 6dB. A total gain of 19 +6 = 25dB is therefore required.

The upper board is the main L&R bus mix amp. On the front panel of this board are the AUX return controls consisting of level and pan controls for each of the two AUX returns. The reason they are on the main L&R bus mix amp is because the AUX returns need to be fed to the L&R mix buses so this is a convenient place to put them. Again a TLA board is used but this time a pair of 10K:10K input transformers is fitted to provide balanced input to the AUX returns. The transformer outputs feed the level and pan controls, the output of which feeds the L&R mix buses via 47K resistors. The two amplifiers on this board act as the master L&R mix amps. As before the mix bus signals end up at the master level control but in this case the master L&R fader is external to the module. As before there are four channels feeding the master L&R buses but in this case the AUX returns also feed it. With 47K bus feed resistors and a 10K master fader, the the total bus loss is just under 21dB and if we need a balanced output then the make up gain will need to be set to about 21 + 6 = 27dB

The AUX send board is complete and ready for testing. The master L&R board is waiting for the pan pots to arrive.